Feature of the Swing Check Valves

The following are the features of the Swing Check Valves

- These types of the valves are very easy to maintenance.

- The sealing is done using the EPDM vulcanized rubber that provides the best sealing capability.

- The discs that are used in this valve are very light weight and requires minimum force for operation.

- The movement of the disc is in the both direction and can be moved in the horizontal or the vertical direction.

- The swing check valves are manufactured using the best quality raw materials.

The best quality of the swing check valves is manufactured using the best quality raw materials and after passing the strict quality check they are handed over to the customers. We are the leading swing check valve supplier in Ahmedabad and the product is easily supplied to the different part of the India. Also the swing check valve exporter in Gujarat that is exporting the swing check valves to the several foreign countries that also at the affordable price. Kindly contact us for more details we will provide you the complete solution related to the swing check valves that also at the affordable price.

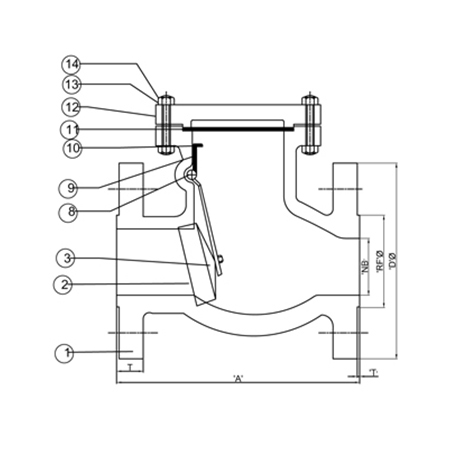

| PNO. | PART NAME | QTY | MATERIAL |

| 1 | BODY | 1 | ASTM A 216 GR. WCB/ IS 210 Gr. 220 C.I. |

| 2 | SEAT RING | 2 | 13% Cr. SS FACING (AISI SS-410) |

| 3 | DISC | 1 | 13% Cr. SS FACING (AISI SS-410) |

| 4 | HINGE | 1 | ASTM A 216 Gr. WCB |

| 5 | WASHER | 1 | S.S. AISI 410 |

| 6 | DISC NUT | 1 | ASTM A 194 Gr. 2H / M.S. |

| 7 | SPLIT PIN | 1 | S.S. AISI 410 / M.S. |

| 8 | HINGE PIN | 1 | S.S. AISI 410 / M.S. |

| 9 | BRACKET | 1 | ASTM A 216 Gr. WCB |

| 10 | BRACKET BOLT | 2 | ASTM A 193 Gr. B7 / M.S. |

| 11 | GASKET | 1 | SS SPIRAL WOUNDED |

| 12 | COVER | 1 | ASTM A 216 GR. WCB/ IS 210 Gr. 220 C.I. |

| 13 | COVER STUD NUT | AS REQD | ASTM A 194 Gr. 2H / M.S. |

| 14 | COVER STUD | AS REQD | ASTM A 193 Gr. B7 / M.S. |

| CLASS 150 | |||||

| SIZE ‘NB’ | ‘A’ | ‘D’ | ‘T’ | ‘RF’ | ‘L’ |

| 1″/15 | 127 | 108 | 11 | 51 | 1.6 |

| 11/4″/32 | 140 | 117 | 11 | 63 | 1.6 |

| 11/”2 /40 | 165 | 127 | 11 | 73 | |

| 2″ / 50 | 203 | 152 | 12 | 92 | 1.6 |

| 21/2″/65 | 216 | 178 | 14 | 105 | 1.6 |

| 3″/80 | 241 | 190 | 16 | 127 | 1.6 |

| 4″/100 | 292 | 229 | 17 | 157 | 1.6 |

| 5″/125 | 330 | 254 | 19 | 186 | 1.6 |

| 6″/150 | 356 | 279 | 24 | 216 | 1.6 |

| 8″/200 | 495 | 343 | 24 | 270 | 1.6 |

| 10″/250 | 622 | 406 | 25 | 324 | 1.6 |

| 12″/300 | 698 | 483 | 25 | 381 | 1.6 |

| 14″/350 | 787 | 533 | 24 | 413 | 1.6 |

| 16″/400 | 864 | 597 | 24 | 470 | 1.6 |

| 18″/450 | 978 | 635 | 24 | 534 | 1.6 |

| 20:/500 | 978 | 698 | 24 | 584 | 1.6 |

| 24″/600 | 1296 | 813 | 24 | 592 | 1.6 |

| CLASS 300 | ||||

| ‘A’ | ‘D’ | ‘T’ | ‘RF’ | ‘L’ |

| 165 | 124 | 17 | 51 | 16 |

| 229 | 133 | 19 | 63 | 1.6 |

| 241 | 156 | 21 | 73 | 1.6 |

| 267 | 165 | 22 | 92 | 1.6 |

| 292 | 190 | 25 | 105 | 1.6 |

| 317 | 210 | 28 | 127 | 1.6 |

| 356 | 254 | 32 | 157 | 1.6 |

| 400 | 279 | 35 | 186 | 1.6 |

| 444 | 317 | 36 | 216 | 1.6 |

| 533 | 381 | 41 | 270 | 1.6 |

| 622 | 444 | 48 | 324 | 1.6 |

| 711 | 521 | 51 | 381 | 1.6 |

| 838 | 584 | 54 | 413 | 1.6 |

| 864 | 648 | 57 | 470 | 1.6 |

| 978 | 711 | 60 | 534 | 1.6 |

| 1016 | 775 | 63 | 584 | 1.6 |

| 1346 | 914 | 70 | 592 | 1.6 |

| CLASS 600 | |||||

| SIZE ‘NB’ | ‘A’ | ‘D’ | ‘T’ | ‘RF’ | ‘L’ |

| 1″/15 | 216 | 124 | 24 | 51 | 6.4 |

| 11/4″/32 | 229 | 133 | 27 | 63 | 6.4 |

| 11/”2 /40 | 241 | 156 | 28 | 73 | 6.4 |

| 2″ / 50 | 292 | 165 | 32 | 92 | 6.4 |

| 21/2″/65 | 330 | 190 | 35 | 105 | 6.4 |

| 3″/80 | 356 | 210 | 38 | 127 | 6.4 |

| 4″/100 | 432 | 273 | 44 | 157 | 6.4 |

| 5″/125 | 508 | 330 | 51 | 186 | 6.4 |

| 6″/150 | 559 | 356 | 54 | 216 | 6.4 |

| 8″/200 | 660 | 419 | 62 | 270 | 6.4 |

| 10″/250 | 787 | 508 | 70 | 324 | 6.4 |

| 12″/300 | 838 | 559 | 73 | 381 | 6.4 |

| 14″/350 | 889 | 603 | 76 | 413 | 6.4 |

| 16″/400 | 991 | 686 | 82 | 470 | 6.4 |

| 18″/450 | 1092 | 743 | 89 | 534 | 6.4 |

| 20:/500 | 1194 | 813 | 95 | 584 | 6.4 |

| 24″/600 | – | – | – | – | – |

| TEST PRESSURE | |||

| CLASS | HYDROSTATIC | AIR | |

| BODY | SEAT & BACKSEAT | SEAT | |

| 150 | 30 Kg/cm2 | 22 Kg/cm2 | 6 Kg/cm2 |

| 300 | 76 Kg/cm2 | 55 Kg/cm2 | 6 Kg/cm2 |

| 600 | 150 Kg/cm2 | 110 Kg/cm2 | 6 Kg/cm2 |

DESIGN FEATURES :

- MANUFACTURING STANDARDS : BS 1868/ANSI B 16.34 / API 6D

- FACE TO FACE DIMS. AS PER ANSI B 16.10

- ENDS FLANGED & DRILLED AS PER ANSI B 16.5 RF.

- TESTING AS PER BS : 5146

- AVAILABLE IN CLASS 900 & 1500

- NON-SLAM ARRANGEMENT ON REQUEST

- AVAILABLE WITH BYE-PASS ARRANGEMENT

- AVAILABLE IN SS-304 / SS-316

NOTE :- ALL DIM. ARE IN MM UNLESS OTHERWISE SPECIFIED